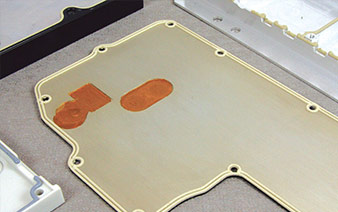

Environmental Sealing Flat Gaskets

Flat gaskets can be cut by CNC die-less knife cutting systems, rule dies, kiss cut or more complex shapes by water jet cutting. Compression stops or collars can also be incorporated, this leads to reduced hardware costs and negates the need for fixings to be torqued to prevent over compression and damage to the gasket. Self-adhesive backing can be applied to the materials prior to cutting.

Kemtron has the capability to produce many designs and styles of flat gaskets. We have a versatile process of manufacture, which is ideally suited for development and pre-production through to full production volumes. Modern tooling using CNC die-less knife cutting systems enable complex shapes to be produced whilst maintaining tight, repeatable tolerances. Single or multipart tool configurations allow for efficient, economical production techniques.

Flat gaskets are produced from sheet while larger gaskets can be cut from fabricated picture frames.

This option has the advantage of saving material and allows larger gaskets to be produced economically. This is facilitated by our in-house tool making and silicone moulding facilities. Fabricated frames use either extruded or moulded flat section that is joined by vulcanizing the polymer.

This process has allowed Kemtron to produce gaskets up to 2 meters long, with the same mechanical integrity as is found in a single part gasket cut from sheet. This method of manufacture often offers cost savings over cutting from sheet with subsequent loss of waste material. During this process compression stops or collars can also be incorporated. This leads to reduced hardware costs and negates the need for fixings to be torqued to prevent over compression and damage to the gasket.

Our experience in laminating allows us to apply self-adhesive backing tape to even the most difficult materials such as silicone, regardless of quantities. We use a range of high performance tapes suitable for all conditions.

Kemtron has in house slitting capability, which allows us to convert sheet or log materials into strip or coils. This flexible technique with short lead times allows materials to be supplied to exact customer requirements with low minimum order quantities.

- Fluorosilicone

- Solid silicone

- Silicone tube

- Sponge silicone

- Neoprene

- EPDM

- Poron

- Other materials – Please enquire

- Continuous lengths up to 5 mtrs long for slit coils

- Fabricated gaskets to customer’s drawings

- Can be fitted with compression limit stops or collars

- Easily assembled using the self-adhesive backing option. (Self-adhesive backing is an assembly aid only)

- A broad range of sizes available

- A large range of materials to suit many climatic conditions

- Large fabricated gaskets can be produced economically

- UL flame retardant approved materials are also available.