Conductive Coatings Acrylic Conductive Coating

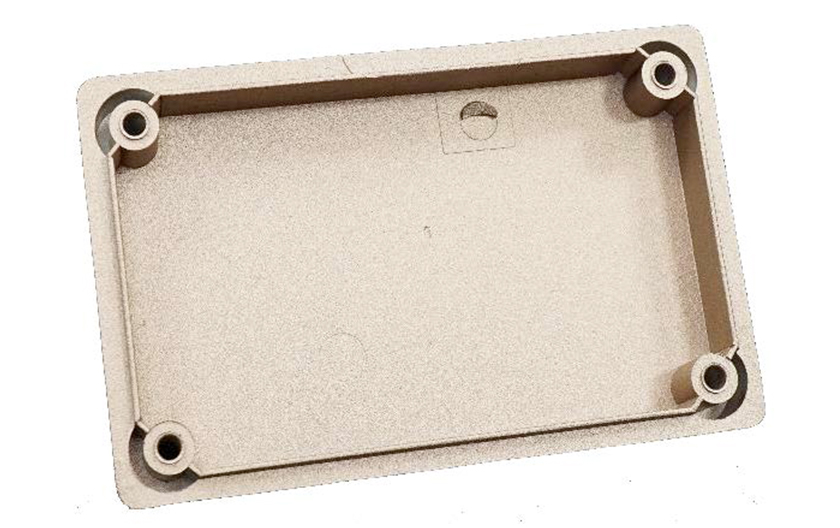

Acrylic is the most commonly used conductive coating. It is widely used on board level applications, electronic enclosures and satellite dishes. It is hard wearing, easy to apply, and adheres well to many surfaces.

The acrylic conductive coatings (AR) series are durable acrylic lacquers pigmented with highly conductive fillers. They are an easy to use solvent based system with no heat cure necessary and provide effective EMI/RFI (electromagnetic interference/radio frequency interference) shielding over a broad frequency range. The coatings have strong adhesion to plastics and provide a smooth, hard, abrasion resistant finish. Drying time is 24 hours at 25°C and 30 minutes at 65°C.

- Available in carbon, nickel, silver coated copper or silver

- Supplied in cans (liquid), jars (liquid) and certain paints in aerosol format

- Strong adhesion to acrylic, acrylonitrile butadiene styrene (ABS), polycarbonate (PC) and other injection moulded plastics

- Mild solvent system

- Smooth, durable and abrasion resistant conductive coating

- Easily applied

- Fast drying time, no heat required

- Service temperature range -40°C to 120°C

- Low volatile organic compound (VOC)

- Does not contain xylene or toluene

- RoHS compliant

Kemtron’s partnership with MG Chemicals enables us to offer a full range of EMI shielding and conductive paints to provide protection against EMI (electromagnetic interference) and RFI (radio frequency interference).

- Carbon Acrylic Conductive Coating

- Nickel Acrylic Conductive Coating

- Silver Copper Acrylic Conductive Coating

- Silver Acrylic Conductive Coating

Carbon Acrylic Conductive Coating is ideal for grounding or low frequency RFI shielding applications such as electric guitars metal detectors, other electronic instruments and other devices affected by the presence of metal.

Nickel Conductive Coating is a good standard choice for shielding plastic enclosures or satellite dishes. It can also be used as a conductive undercoat in many electroplating applications.

Silver Coated Copper Conductive Coating provides superior EMI/RFI shielding to plastic enclosures and is also suitable for some board level applications. It can also be used as a conductive undercoat in many electroplating applications.

Silver Conductive Coating provides the highest level EMI/RFI shielding for electronic enclosures. It is suitable for board level applications and may also be used as an undercoat in most electroplating applications.